Rethinking the Shape of Satellites

For most of the space age, satellites have been boxy affairs, rectangular or cylindrical structures bristling with deployable solar panels, antennas, and instrument booms. The form factor is dictated largely by the constraints of launch vehicle payload fairings and the need to pack as much capability as possible into a compact volume. But a growing number of engineers and mission planners are questioning whether the conventional approach is optimal, and a concept called DiskSat is leading that reassessment.

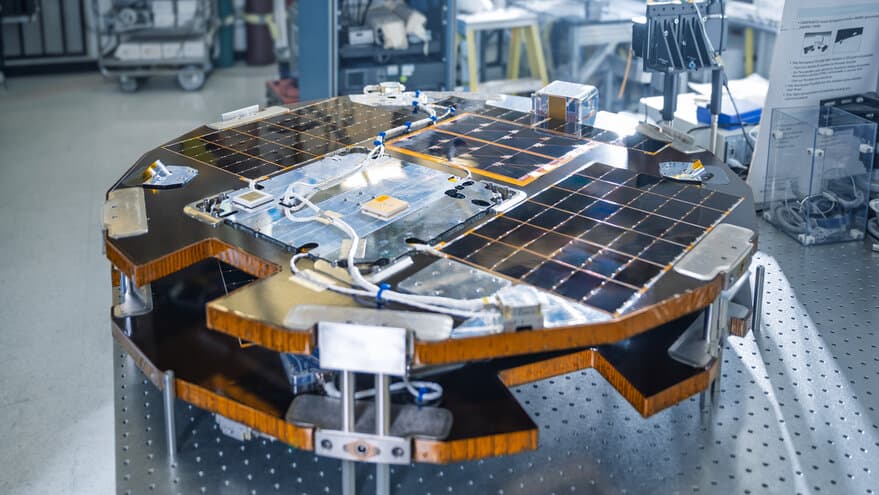

DiskSat, originally developed through research at Aerospace Corporation and refined through several years of prototyping, reimagines the satellite as a flat disk roughly one meter in diameter and just a few centimeters thick. The design eliminates deployable structures entirely, integrating solar cells, antennas, and sensors directly onto the disk's surfaces. The result is a spacecraft that is mechanically simpler, cheaper to manufacture, and dramatically easier to launch in large numbers.

This month, the DiskSat development team announced that it has signed partnership agreements with three additional aerospace companies, bringing the total number of industry collaborators to seven. The new partners span satellite manufacturing, launch services, and ground systems, signaling that the concept is gaining traction across the value chain.

The Engineering Case for Going Flat

The traditional satellite form factor carries hidden costs. Deployable solar arrays require complex hinge mechanisms, shape memory alloy actuators, and extensive testing to ensure they will unfurl correctly in the zero-gravity environment. Deployable antennas introduce similar complexity. Each moving part is a potential point of failure, and the testing regime needed to qualify deployable mechanisms for flight adds months and millions of dollars to a satellite program.

DiskSat sidesteps these challenges by making the entire body of the satellite a functional surface. One face is covered with high-efficiency solar cells. The opposite face serves as a phased array antenna or sensor aperture. The thin edge houses miniaturized avionics, reaction wheels for attitude control, and propulsion hardware. Because nothing deploys, the satellite is ready to operate the moment it separates from the launch vehicle.

Manufacturing Advantages

The flat form factor also lends itself to manufacturing techniques borrowed from the electronics industry rather than traditional aerospace fabrication. DiskSat structures can be produced using printed circuit board manufacturing processes, with conductive traces, thermal management layers, and structural elements built up in a single lamination stack. This approach enables rapid, repeatable production at a fraction of the cost of conventional satellite assembly.

- No deployable mechanisms reduces mechanical complexity by over sixty percent

- PCB-style manufacturing enables production rates of multiple units per day

- Flat profile allows dense stacking for rideshare launches

- Integrated antenna eliminates need for separate communications hardware

- Reduced part count translates directly to improved reliability

Launch Economics Transform

Perhaps the most compelling advantage of the DiskSat form factor is its impact on launch economics. Because the satellites are thin and flat, they can be stacked like plates in a dispenser that fits within standard payload fairings. A single Falcon 9 rideshare mission could carry dozens of DiskSats as secondary payloads, with each satellite sliding out of the stack in sequence. The dense packing ratio means more satellites per launch, which drives down the per-unit cost of getting to orbit.

This is particularly relevant for constellation operators who need to deploy hundreds or thousands of satellites to provide continuous global coverage. The economics of constellation deployment are dominated by launch costs, and any architecture that reduces the number of launches required to populate a constellation has a significant competitive advantage.

Compatibility With Emerging Launchers

The DiskSat team has also been exploring compatibility with emerging small launch vehicles and orbital transfer vehicles. The flat form factor is well suited to the payload bays of vehicles like Rocket Lab's Electron and Firefly's Alpha, and it can be easily accommodated by orbital transfer stages that move satellites from injection orbit to their operational altitude. Two of the new industry partners are launch service providers, suggesting that integration studies are already underway.

New Partners and Their Roles

While the specific identities of all new partners have not been publicly disclosed, the DiskSat team has indicated that the collaborations cover three key areas. The first is advanced materials, with a partner contributing expertise in lightweight composite substrates that could further reduce the mass of the disk structure. The second is ground systems, with a partner developing software-defined ground stations optimized for the phased array communications architecture used by DiskSat. The third is mission applications, with a partner exploring how the flat satellite platform could be adapted for specific use cases including weather monitoring, maritime surveillance, and Internet of Things connectivity.

The breadth of these partnerships reflects the versatility of the DiskSat platform. Unlike highly specialized satellite designs that are optimized for a single mission type, the flat disk form factor can accommodate a range of payloads simply by changing what is mounted on its surfaces. This modularity is attractive to companies that want to address multiple markets with a common hardware platform.

Challenges and Open Questions

The DiskSat concept is not without challenges. The fixed solar array area limits the amount of power available to the satellite, which in turn constrains the types of payloads it can support. High-power instruments such as synthetic aperture radar or high-bandwidth optical communications terminals may require more energy than a one-meter disk can generate. The flat profile also presents attitude control challenges, as the large surface area relative to mass makes the satellite more susceptible to aerodynamic drag in low orbits and solar radiation pressure at higher altitudes.

Thermal management is another area of active development. With all electronics integrated into a thin structure, dissipating waste heat becomes more difficult than in a conventional satellite where components can be spread across a larger volume. The DiskSat team has been experimenting with advanced thermal interface materials and radiative coatings to address this constraint.

Path to Flight

Despite these challenges, the project's momentum is undeniable. A technology demonstration mission is planned for 2027, which will place a functional DiskSat prototype in low Earth orbit for a minimum six-month operational evaluation. The mission will validate the structural, thermal, and communications performance of the design in the actual space environment and provide data needed to refine the platform for commercial production.

For an industry that has built satellites more or less the same way for sixty years, DiskSat represents a genuinely novel approach. Whether it becomes a mainstream platform or remains a niche solution for specific applications, its growing roster of industry partners suggests that the concept has moved well beyond the academic curiosity stage and into serious commercial consideration.